ENVIRONMENT

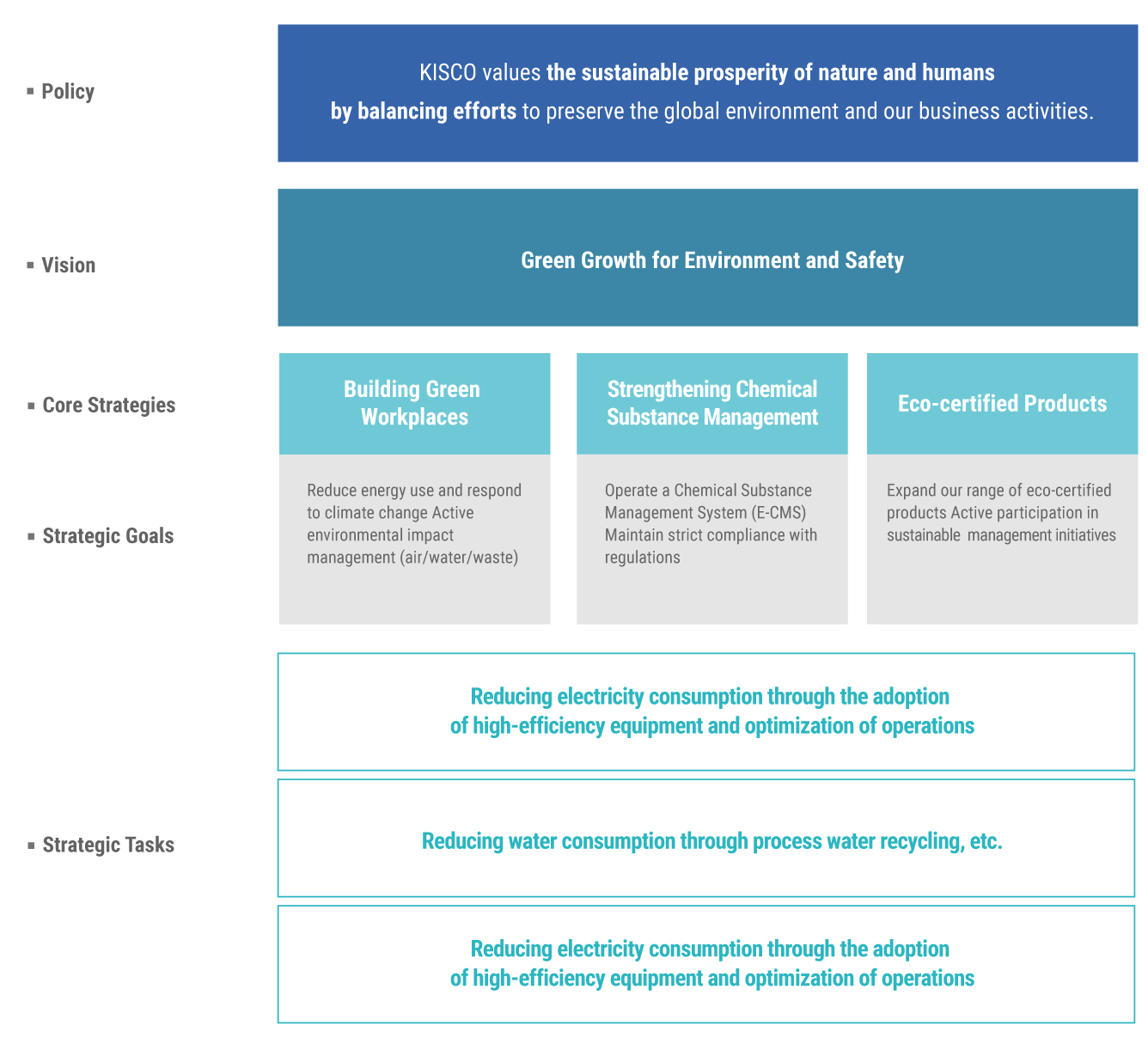

▪︎ Environmental Policies and Goals for Green Growth

| KISCO pursues green growth by maintaining a balance between environmental preservation and business activities, building eco-friendly workplaces that consider both the environment and people, expanding certified eco-friendly products, and strengthening the management of chemical substances. KISCO aims to respond to the climate crisis and minimize the environmental impact that may arise during the product manufacturing process. |

|---|

▪︎ Environmental Management Policy

| KISCO recognizes environmental conservation as a corporate social responsibility and has acquired the global standard certifications ISO 14001 and ISO 45001 for environmental management and occupational health and safety management systems. Based on this, we established and implemented environmental management strategies and detailed action plans for all stages of product development, production and use. |

|---|

| 1. Recognizing that environmental protection is a basic social responsibility of a company, KISCO complies with 1. all laws and regulations on environmental protection. 2. Company-wide efforts to improve systematic and continuous environmental protection. 3. In the entire process of product development, production and use, we do our best to develop technologies that 3. consider environmental preservation. 4. Make environmental information available to stakeholders. 5. We provide and actively support environmental education and opportunities for employees to improve 5. their awareness of environmental preservation. |

|---|

|

※ KISCO has established an integrated “KISCO EHS Management Policy” based on ISO 14001 and ISO 45001.

|

|---|

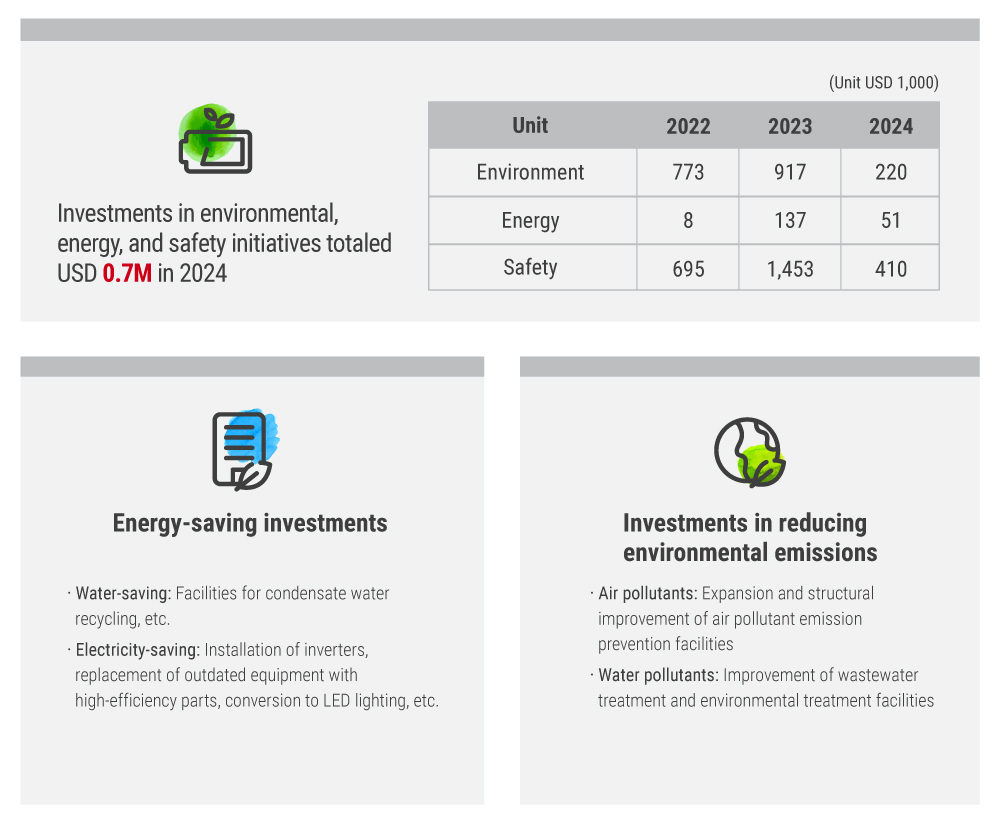

▪︎ Investment for the Environment

| KISCO pursues sustainable environmental management through various activities aimed at reducing environmental impact. We continuously invest in environmental and energy-related initiatives to reduce resource and energy consumption during product manufacturing and to minimize pollutant emissions. |

|---|

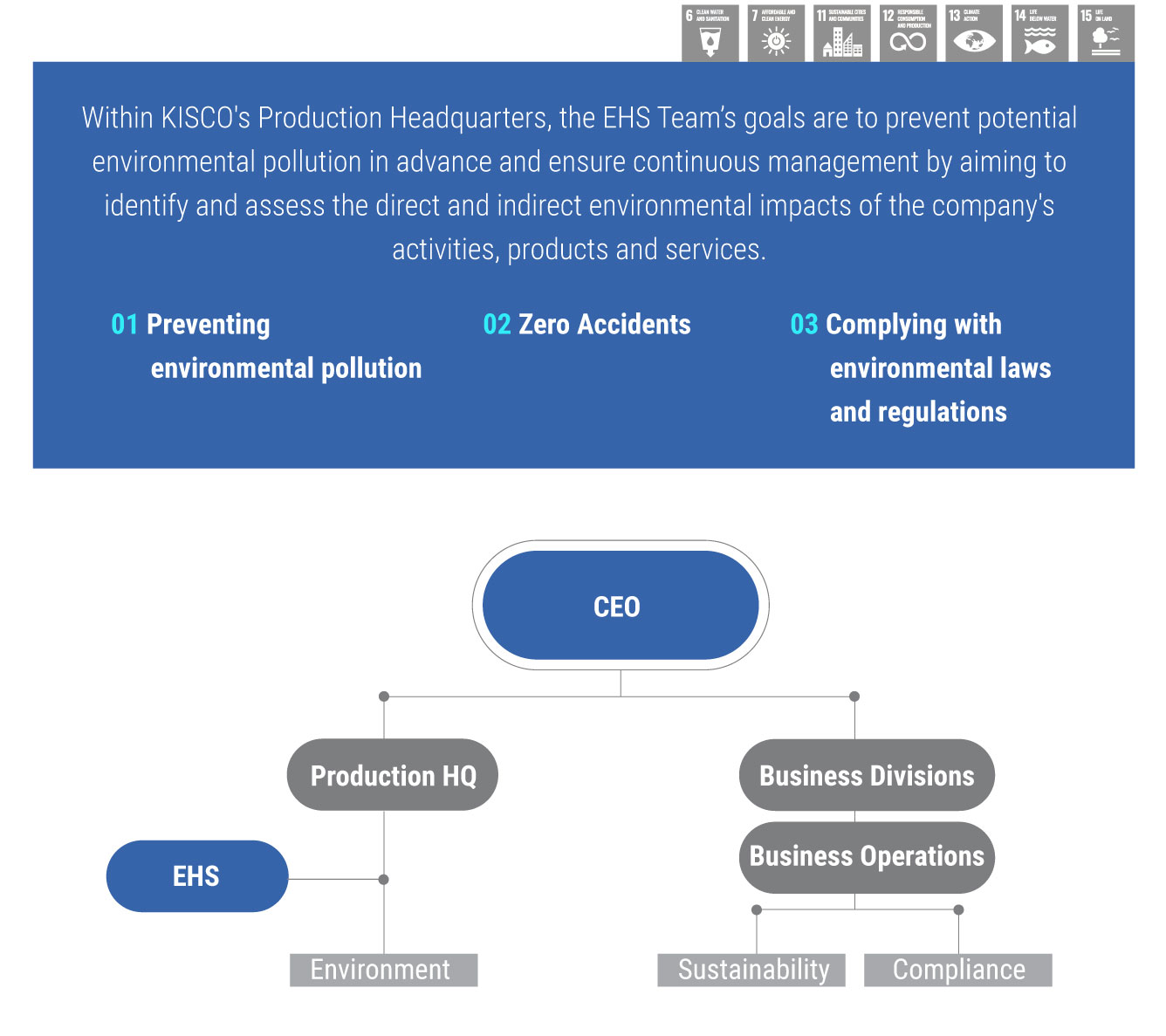

▪︎ EHS, Environmental Organization

▪︎ Environmental Performance Management System:

▪︎ Sustainable Management and ESG Certification Status

| In addition to the global standard certifications ISO 9001, ISO 14001 and ISO 45001 for environmental and occupational health and safety management, KISCO has sustainability certifications applicable to each industry that we work in. We incorporate these regulations into our management practices for sustainable management. |

|---|

| Certificate | Site | First certification year | Certified by |

|---|---|---|---|

| ISO 9001 Quality Management System |

All site | 2005 | Lloyd’s Register Quality Assurance Limited |

| ISO 14001 Environmental Management System |

KIF1, KIF3, KIF4 | 2005 | Lloyd’s Register Quality Assurance Limited |

| ISO 45001 Occupational health and Safety Management System |

KIF1, KIF3, KIF4 | 2005* | Lloyd’s Register Quality Assurance Limited |

| bluesign® SYSTEM bluesign® SYSTEM PARTNER solutions and services for the sustainable textile industry |

KIF1, KIF3, KIF4 | 2010 | bluesign technologies ag |

| Global Organic Textile Standard | KIF1, KIF3, KIF4, KIF5 | 2008 | Ecocert Group |

| ECO Passport by OEKO-TEX® Certification system for chemicals, colorants and auxiliaries used in the textile industry |

KIF5 | 2020 | TESTEX AG |

| FSSC 22000 Food Safety Management Systems |

JMC | 2018 | SGS United Kingdom Ltd. |

| HAS23000 Halal Assurance System |

JMC | 2020 | Fatwa Commission of MU |

*OHSAS 18001 initial certification year, transition from OHSAS 18001 to ISO 45001 successfully passed in 2021.

※ KIF: Kyung-In Factory. Incheon Factory (KIF1, KIF2)/ Ansan Factory (KIF3)/ Sihueung Factory (KIF4,KIF5)/ Iksan Factory (KIF6)/ Yesan Factory (KIF7)

▪︎ Environmental Management Education

| KISCO enhances employees’ environmental management awareness and conducts specialized environmental management training tailored to job roles to strengthen environmental risk management and prevent accidents. |

|---|

| Category | Unit | Training hour | Target of training | Completion count* |

|---|---|---|---|---|

| Training for air quality management technology | 3 years | 28 hours | Environmental Manager | 2 |

| Training for water quality management technology | 3 years | 28 hours | Environmental Manager | 2 |

| Education for hazardous chemical substance managers | 2 years | 16 hours | Hazardous chemicals manager | 8 |

| Education for hazardous chemical substance handlers | 2 years | 16 hours | Hazardous chemicals handler | 117 |

| Education for workers in hazardous chemical related businesses | Annual | 2 hours | Non-chemical Handler | 101 |

*Number of people who completed the training course in 2024.

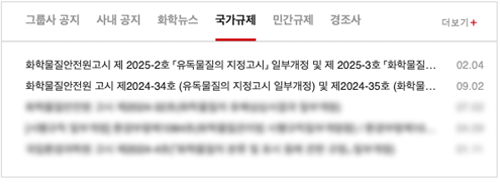

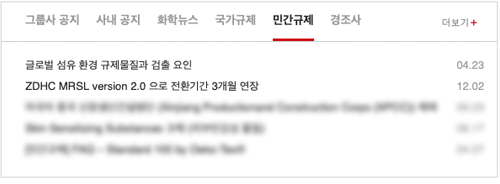

▪︎ Environment Management Laws/Regulations and Environmental Accident Response

| To respond to strengthening environmental regulations, both domestically and internationally, KISCO has established dedicated teams for each area and continuously monitors all related laws and regulations, as well as guidelines from various domestic and international government and private initiatives. KISCO has established procedures to comply with these regulations and introduced management systems to manage each item. |

|---|

| Management areas | Laws/regulations | Department in charge |

|---|---|---|

| Environmental management | Clean Air Conservation Act, Enforcement Decree of the Water Environment Convervation Act, etc. |

EHS, Environment |

| Substance management | Act on Registration and Evaluation of Chemical Substances, Chemical Substances Control Act, etc. |

Compliance, Sustainability |

| Health and safety management | Serious Accident Punishment Act, Occupational Safety and Health Act, etc. |

EHS, Safety |

| ▪︎ Monitoring Status of Laws/Regulations |

|---|

|

|

|---|

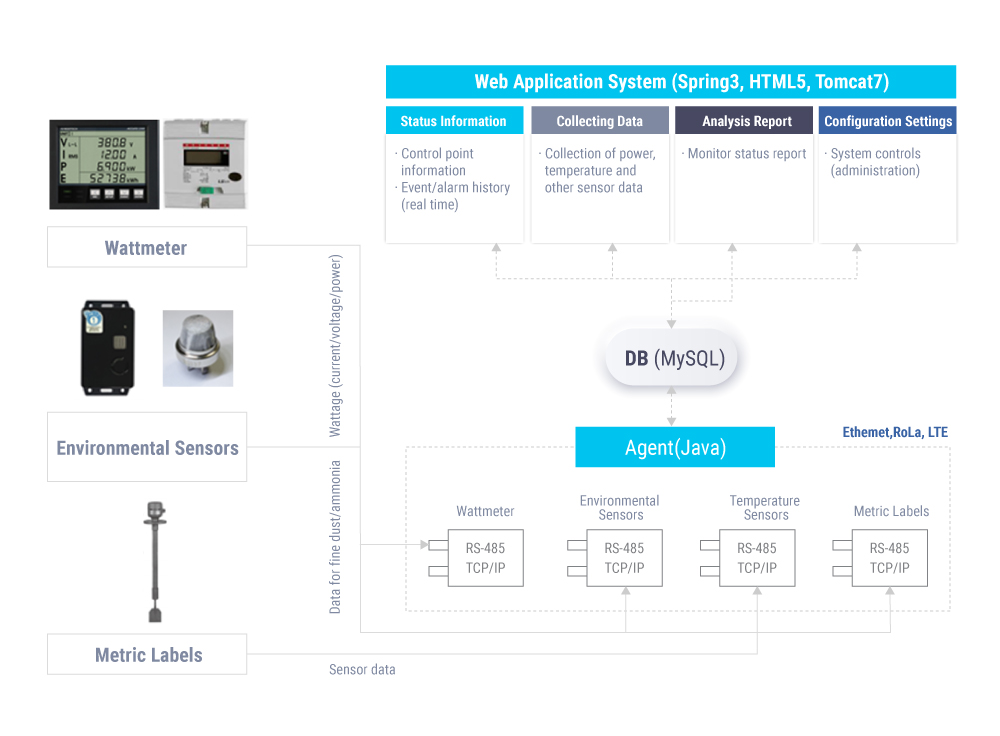

▪︎ Environment Management System

| KISCO has obtained ISO 14001 certification, a global standard certification for environmental management systems, at some of its facilities and has established the integrated KISCO Health, Safety and Environmental Management Policy. This policy is deployed across all facilities. We also operate environmental monitoring systems and chemical management systems to efficiently monitor energy resources, pollutants, chemicals and other environmental-related aspects and to manage environmental risks in real-time. |

|---|

| ▪︎ Environmental Monitoring KISCO manages environmental impacts by adopting various systems such as monitoring environmental substances, managing chemical substances, complying with regulations and carrying out environmental impact assessments. A key tool for managing our data is our Environmental Management System (EMS). The system enables real-time measurement-based monitoring of energy resources and data through a network of environmental sensors. The system is underpinned by an integrated environmental monitoring system that includes monitors for electricity and air quality. – Real-time measurement-based monitoring of energy resources and data through a network of environmental sensors. – Integrated environmental monitoring system that includes monitors for electricity and air quality |

|---|

| ▪︎ Chemical Substances Management System KISCO’s electronic Chemical substances Management System (eCMS) is a substance management and regulation database. It includes over 40,000 domestic and 400,000 overseas-registered chemical substances. It assists compliance with 15 environmental safety regulations including the Korean Chemical Evaluation Act, the Korean Chemicals Act, the Industrial Safety Act and similar regulations in 47 other countries. The system enables the proactive review of information related to purchase, manufacturing, handling, licensing, performance management and partnering. The system also has an integrated MSDS inventory management module. |

|---|

| ▪︎ Environmental Impact Assessment Management – ISO 14001 The environmental team of KISCO established a process to conduct initial, regular and random environmental impact assessments according to the following procedures. Following the audits, corrective actions are initiated if any activities deviate from internal regulations. 1) Evaluation of internal and external issues and stakeholder requirements 2) Evaluation of process, environmental aspects, environmental impacts and materiality issues 3) Air, water quality, waste, noise/vibration, odor, soil contamination, resource/energy consumption audits |

|---|

▪︎ Supply Chain Risk Management Policy

| KISCO aims to grow together with its partners by building a sustainable supply chain based on mutual cooperation, with a strong focus on human rights and the environment. KISCO is committed to recognizing and managing supply chain transparency and continues to improve its ESG-related risk assessment system each year — not only evaluating financial and quality risks related to product supply, but also strengthening diagnostic criteria for non-financial risks such as human rights and environmental impact. |

|---|

| ▪︎ Supplier Code of Conduct |

|---|

| KISCO’s Supplier Code of Conduct was established to ensure that suppliers uphold human rights and environmental values while pursuing mutual respect and co-prosperity with KISCO. The goal is for suppliers to participate in creating sustainable value through social responsibility. KISCO’s suppliers are required to comply with this code. |

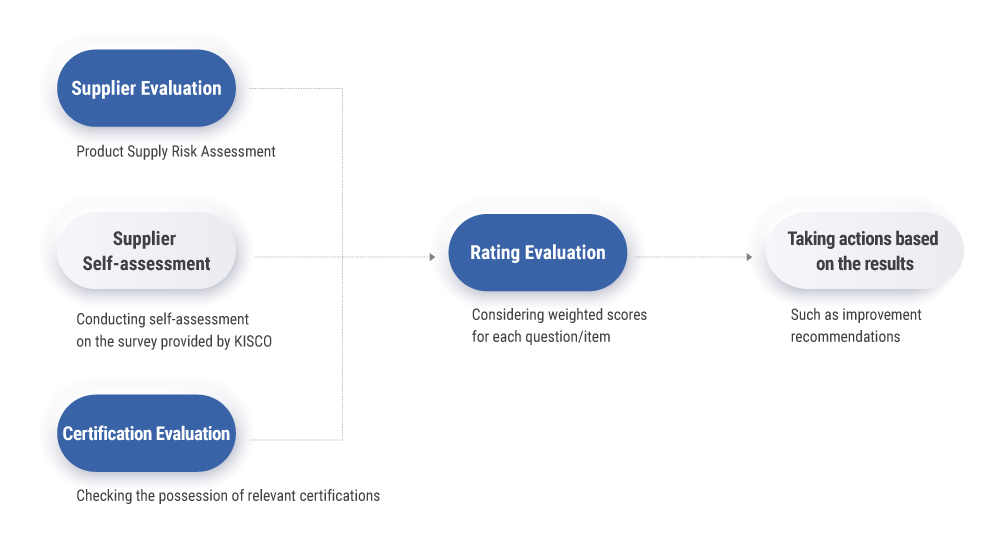

| ▪︎ Supply Chain Risk Management Process |

|---|

| KISCO regularly assesses and manages risk factors within its supply chain. To ensure transparency in these evaluations, multi-layered evaluation methods are used. The company continues to advance its processes to build a more responsible supply chain. |

▪︎ Environmental Impact Management

▪︎ Pollutant Emissions Management Activities

| KISCO strictly complies with legal emission standards for air and water pollutants and has established even stricter internal management standards to further minimize the release of environmental pollutants. |

|---|

▪︎ Reduction of air pollutant emissions

| KISCO establishes internal management standards that are more stringent than the legal emission standards and continues to invest in facilities to prevent air pollution, aiming to minimize the emission of air pollutants. |

|---|

| ▪︎ Investment in RTO and HTO Facilities |

|---|

| In order to prevent air pollution and to enable energy savings through the reuse of waste heat, RTO (Regenerative Thermal Oxidizer) and HTO (Heat Transfer Oxidizer) facilities have been installed. These facilities reduced hydrocarbon emissions by 99.9% and save approximately 50% of energy usage for heating by utilizing recovered waste heat. |

|---|

|

|

| ▪︎ Environmental Impact Target and Performance Management ▪︎ – Management of pollutant discharge after installation of KIF4 HTO ▪︎ |

|---|

Classification | Before installation | Management objective | 2023 | 2024 |

Reduction rate of hydrocarbon emissions | 70.0% | 99.0% | 99.9% | 99.9% |

| ▪︎ Steam recycling from HTO operation at KIF4 |

|---|

| – A total of 419 MT of recycled steam in 2024 was used to produce hot water, which was reused as cleaning water. |

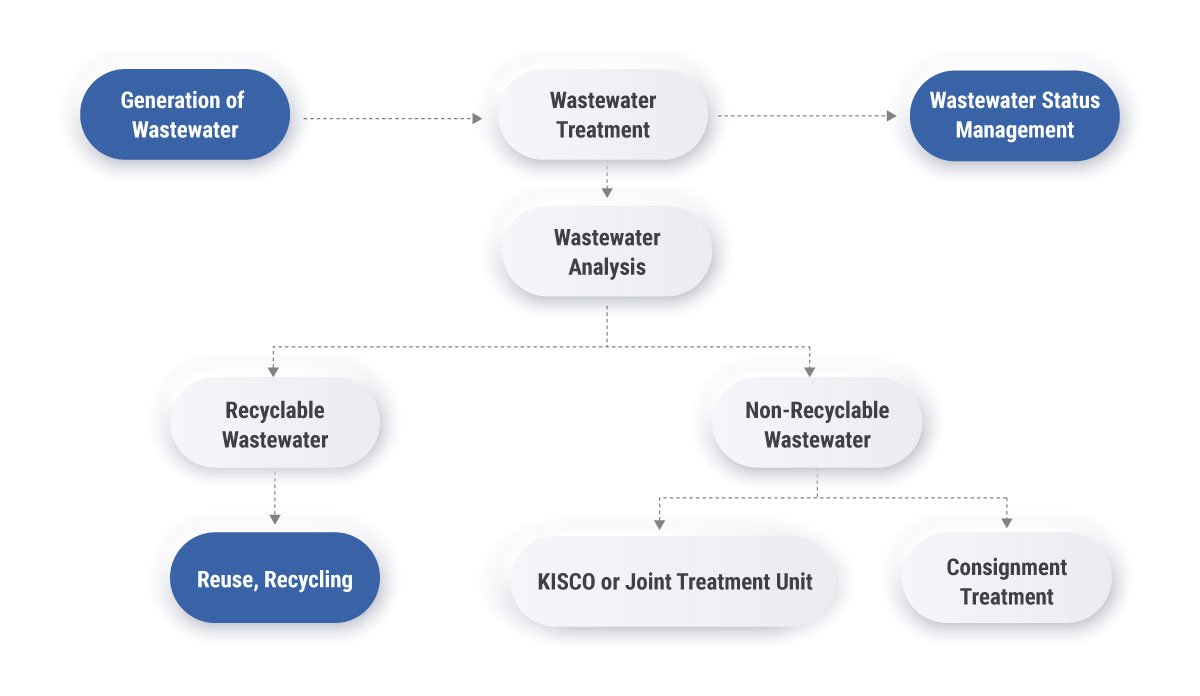

▪︎ Reduction of Water Pollutant Emissions

| To minimize the discharge of water pollutants, KISCO establishes and manages more stringent internal management standards than the legal discharge limits specific to each area where its facilities are located. Recycled water is used in many areas and some domestic facilities have their own wastewater treatment plants. |

|---|

| ▪︎ Wastewater Treatment by Facility |

|---|

| Among KISCO’s seven domestic manufacturing facilities, five are equipped with in-house wastewater treatment facilities. Wastewater and waste liquid are actively reused and recycled. |

|

|---|

| ※ KIF stands for Kyung-In Factory, referring to: Incheon (KIF1, KIF2) / Ansan (KIF3) / Siheung (KIF4, KIF5) / Iksan (KIF6) / Yesan (KIF7) |

|---|

| ▪︎ Wastewater Treatment Process |

|---|

|

|

▪︎ KISCO Resource Circulation

| KISCO reviews the recycling of waste resources, such as byproducts and waste materials, that are generated during manufacturing processes. We aim to expand the practice of resource circulation through continued reuse and recycling of waste resources. |

|---|

| ▪︎ Process for Reviewing Waste Recycling |

|---|

| ▪︎ 2024 Waste Resource Recycling Cases and Performance |

|---|

| – Reuse of Steam Condensate: 10,037 tons |

| – Reuse of Excess Steam during HTO Operation: 419 tons |

| – Recycling of Waste Organic Solvents and Residual Liquids: 97 tons |

▪︎ Environmental data management

| ▪︎ GHG (t-CO2 eq) Emission Management |  |

|---|

|

|---|

| – Calculated based on national methodology from the Ministry of Environment’s notification: Guidelines on Emissions Reporting – and Verification for the Greenhouse Gas Emissions Trading Scheme (MOE Notification No. 2021-10) – The aforementioned greenhouse gas emissions refer to the total emissions aggregated from the domestic business sites of KISCO, and neither – the aggregated emissions nor individual sites are subject to the Ministry of Environment’s greenhouse gas emissions trading system. 1) Scope 1: Carbon emissions potentially generated during the manufacturing process of LNG, gasoline, diesel, and the company’s products, 1) calculated based on chemical formulas. 2) Scope 2: Calculated based on the supplier’s invoices for electricity and steam usage. 3) Emissions intensity = Total greenhouse gas emissions / Total revenue. |

|---|

| ▪︎ Management of Air and Water Pollutant Emissions |  |

|---|

|

||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1) Based on data submitted to the Korean Government Stack Emission Management System (SEMS) or self-measurement records measured 1) by an external company. The total emissions for each domestic factory are summed – – Self-measurement record (measurement of external companies) standard for workplaces with less than 3 types (KIF3,5,6,7) that are not – – subject to SEMS input 2) Based on data summed and submitted to the Korean National Pollutant Survey (water quality) and the total emissions of KISCO notified 2) by the wastewater plant or consignment treatment company – – Wastewater facilities, or with self-measurement records based on the data submitted to the Korean National Pollutant Survey – – Discharge water after treatment at a joint treatment facilities in the area 3) From 2022, the nationwide pollution source survey (water quality) management item will be changed from COD to TOC and reflected 3) in our management item. – – Errors were found in the calculation details of the existing posted content on water pollution substances, and it has been corrected. 4) The total discharge volume of each domestic business site of Kyeongin Yanghang, as notified by the submitted data from the nationwide 4) pollution source survey (water quality) and by the joint or consigned treatment facilities: – – For businesses with wastewater treatment facilities and self-measurement record books, based on the submitted data from the nationwide – – pollution source survey. – – For businesses with joint or consigned treatment facilities, based on the data provided in the notification. |

|---|

| ▪︎ Waste Management by Disposal Method |  |

|---|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| * Calculated by aggregating data from the Allbaro System reports for waste generation by KISCO’s domestic sites, and data * from waste disposal/recycling invoices issued by consigned processors. * Recycled waste rate = recycled waste/total waste * A new category for “neutralized waste” has been added. |

|---|

| ▪︎ Ratio of Eco-Friendly Vehicles Owned |

|---|

| KISCO continues to replace newly acquired or outdated business-use vehicles with eco-friendly models to reduce environmental impact. |

|---|

|

|---|

| * Based on vehicles owned or registered under the corporation’s name * Eco-Friendly Vehicle Ownership Ratio = 25 electric/hybrid vehicles / 71 total vehicles (as of 2024) |

|---|

▪︎ Energy and Water Resource Usage Reduction Activities

| KISCO practices energy efficiency improvements for climate change adaptation, investing in facilities to reduce energy usage, implementing smart eco-factory projects, and conducting campaigns for household energy and water usage reduction. In addition, it sets energy and water resource reduction targets for each facility based on production plans, establishes activity plans for reduction, and manages performance accordingly. Some facilities also use recycled steam for all steam required for manufacturing. |

|---|

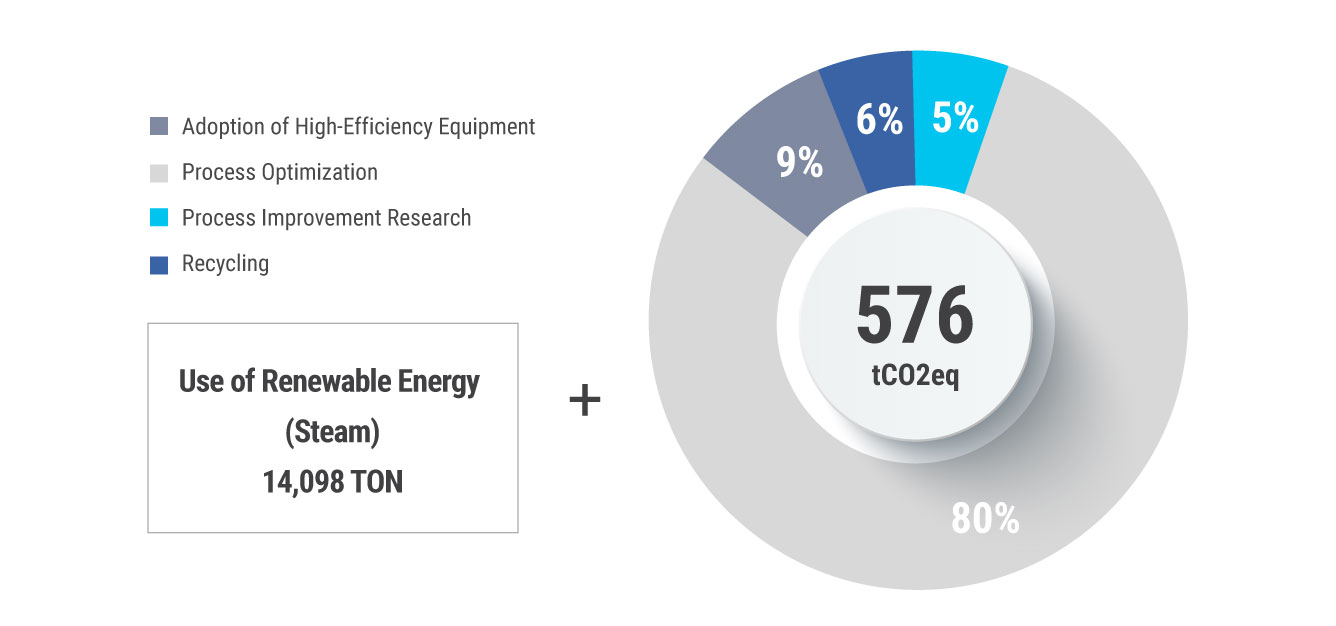

| ▪︎ Performance of Greenhouse Gas Reduction Projects through Energy Savings |

|---|

| Each KISCO manufacturing site operates GHG reduction projects through energy savings. Sites establish their own KPIs for reducing energy use and track reduction results through efforts such as introducing high-efficiency equipment/parts, process optimization, process improvement R&D, recycling, and the use of renewable energy. 2024 Greenhouse Gas Reduction Project Results |

|---|

|

| ▪︎ External Wall Insulation |

|---|

| KISCO has implemented insulation on its exterior walls, resulting in an annual energy saving of 65,801kWh for heating and cooling needs. |

|---|

Item | Before installation | Objective | 2022 | 2023 | 2024 |

Effectiveness of external wall insulation construction | - | 23.6tCO2eq | 17.5tCO2eq | 23.8tCO2eq | 30.2tCO2eq |

| Before construction | After construction |

|

|

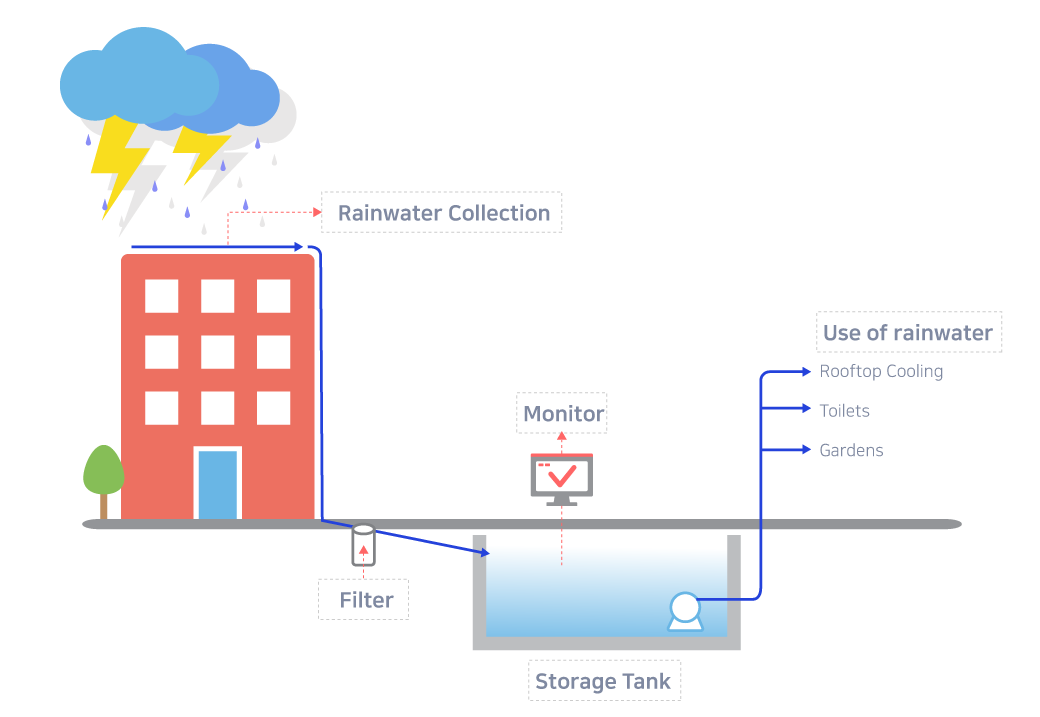

| ▪︎ Rainwater Harvesting |

|---|

| Through the Smart Eco-Factory project, KISCO converted sewage treatment facilities into rainwater utilization facilities. Collected rainwater was then used for production processes, thereby reducing the consumption of tap water. * In 2024, rainwater reuse volume was 216.0m³, achieving 80% of the target. |

|---|

Item | Before installation | Objective | 2022 | 2023 | 2024 |

Outstanding recycling performance | - | 268.7m³ | 312.0m³ | 272.0m³ | 216.0m³ |

|

|

▪︎ Energy Usage Management

| Sort | Unit/Year | 2022 | 2023 | 2024 |

|---|---|---|---|---|

| Total energy consumption | TJ | 579 | 516 | 521 |

| Unit¹⁾ | TJ/10 mil KRW | 0.20 | 0.21 | 0.19 |

| In-house Energy Usage Targets | TJ | 562 | 521 | 527 |

| (Achievement Rate of Targets) | % | 103% | 99% | 99% |

| Energy Consumption Management²﹚ | TJ | 45 | 40 | 40 |

| (Renewable energy usage ratio) | % | 8% | 8% | 8% |

* Guidelines on Reporting and Verification of Emissions under the Emissions Trading Scheme” (Notification No. 2021-10) (2022 basis)

* The above greenhouse gas emissions are the sum of the total emissions limited to the domestics business sites of KISCO and are not subject to

– the greenhouse gas emission trading system of the Korean Ministry of Environment.

1) Unit: Energy Usage Total Emissions / Total Revenue

2) The amount of energy from renewable sources provided by the supplier

▪︎ Water Usage Management

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1) Based on the water bill issued per business location 1)– Incheon (KIF1, KIF2) / Gyeonggi (KIF3, KIF4, KIF5) / Iksan, Yesan (KIF6, KIF7) / Seoul Office (Office building, Research institute). |

|---|

▪︎ Eco-friendly Certification and Initiative Activities

| As a member of the Global Green Certification and Related Initiative, we design and produce environmentally friendly and secure products. |

|---|

Eco-friendly Certification

|

▪︎ bluesign® |

|

|---|---|

| KISCO has been certified as a bluesign® system partner since 2010. The bluesign® system is a sustainable certification system for the entire textile industry supply chain. The system oversees and manages production processes for five key areas: corporate resource productivity, consumer safety, air pollution, water pollution, and work health and safety, and independent audits identify improvements and validate processes. Over 200 of our textile dye products have been approved by bluesign®. More detailed information can be found via the link below https://www.bluesign.com/en |

|

|

▪︎ GOTS (Global Organic Textile Standard) |

|

|---|---|

| The goal of GOTS is to define the requirements that organic textile products must meet, ensuring the safe use of textile products by ensuring that the entire process is environmentally and socially responsible from harvesting raw materials to final labeling. Our company has received GOTS certification for over 150 dye and ink products. KISCO’s compliance with GOTS is certified by ECOCERT. More information can be found via the link below. https://global-standard.org/ |

|

|

▪︎ ECO PASSPORT by OEKO-TEX® |

|

|---|---|

| ECO PASSPORT BY OEKO-TEX® is a chemical, dye and additive certification used in textile and leather production. This means that they are responsible for production and handling chemicals to protect people and the environment, and our certified dye and ink products are proof that they are suitable for sustainable textile production. Our company has passed the certification standard for over 40 ink products. More information can be found via the link below. https://www.oeko-tex.com/en/our-standards/oeko-tex-eco-passport |

|

Initiative Activities

|

▪︎ ZDHC |

|

|---|---|

| The ZDHC (Zero Discharge Hazardous Chemicals) Foundation is a cooperative organization composed of brands, factories, chemical manufacturers and certification bodies, aimed at minimizing environmental pollution throughout the textile industry and improving sustainable chemical management within the supply chain. Managing harmful substances in the manufacturing process is essential, and the foundation operates various programs to integrate regulatory targets and levels to apply them on-site. KISCO has been an active ZDHC Signatory Chemical Formulator since 2019. Over 400 of our dye and ink products comply with both product hazard and production environmental assessment criteria and are registered on the ZDHC Gateway. Further information can be found via the following link. https://www.roadmaptozero.com/ |

|

|

▪︎ SCTI |

|

|---|---|

| SCTI (Sustainable Chemistry for Textile Industry), launched in 2020, is an alliance of leading chemical companies that aims to enable the textile and leather industries to apply cutting-edge sustainable chemical solutions to protect factory workers, local communities, consumers, and the environment. Our company, along with Archroma Textile Effects, CHT Group, Pulcra Chemicals, Rudolf Group, and Tanatex Chemicals, is a founding member of SCTI. SCTI and its members are collaborating with bluesign® to develop the Sustainable Chemistry Index, a sustainability index for products and companies. More information is available via the link below. https://scti.org/ |

|

▪︎ Environmentally-friendly Sales Performance

| KISCO calculates its eco-friendly sales based on the annual sales performance of products certified by third-party environmental standards such as GOTS and ECO-PASSPORT. In 2024, the number of products certified with GOTS increased by approximately 30% compared to the previous year, resulting in growth in both eco-friendly sales volume and ratio. KISCO plans to continue expanding its portfolio of certified eco-friendly products. |

|---|

| Item | Unit/Year | 2022 | 2023 | 2024 |

|---|---|---|---|---|

| Environmentally Friendly Sales¹⁾ | USD Mil. | 100 | 91 | 100 |

| Environmentally Friendly Sales Ratio²⁾ | % | 52 | 55 | 73 |

1) Certified products may vary by year, and sales performance is based on the products certified for each specific year.

2) Environmentally Friendly Sales Ratio = Environmentally Friendly Sales / Total Sales of KISCO