INKS FAQ

Welcome to the FAQ page for inks

| Select your area of interest from the list on the left and expand each item to find the answers to your questions. |

|---|

Process innovation

| PAPIJET inks are manufactured by KISCO in Korea. KISCO is a large-scale chemical manufacturer that has been making dyes and colors for over 50 years. Many digital textile ink companies simply formulate their inks in water using powders sourced from a wide variety of suppliers. By contrast, KISCO makes many of our own ink raw materials. In fact, we actually supply ink powders to many other ink manufacturers. Working with a company that actually makes its own raw materials gives our customers greater confidence in the quality of our products and security of our supply chain. |

|---|

Origin

| Our company is based in Korea and we have 10 manufacturing sites there. Our headquarters and main R&D building are located in Seoul. |

|---|

| We are a publicly listed company that has been operating for over 50 years. To read the full history of our company, please visit the relevant part of our website. |

|---|

| KISCO has decades of export experience, ensuring that our customers have supplies when they need them. KISCO’s production is compatible with factory requirements to be Never Out of Stock (NOOS). We directly manufacture in Korea. Our logistics expertise ensures reliable, NOOS supply. |

|---|

Sustainability

| KISCO is a partner in this sustainability alliance of the world’s leading chemical companies. Sustainable Chemistry for the Textile Industry (SCTI) is a not-for-profit organization founded in 2020. Our six founding members – Archroma, CHT Group, Kyung-In Synthetic Corporation (KISCO), Pulcra Chemicals, Rudolf Group, and Tanatex Chemicals – are market leaders who are committed to drive collaboration to achieve sustainable and safe practices for workers, communities, environment, and consumers.

In 2022, SCTI teamed up with bluesign® to create the Sustainable Chemistry Index (SCI), a first-of-its-kind index that enables stakeholders to assess the sustainability of textile chemical products. |

|---|

|

| KISCO is accredited under the world’s leading textile industry compliance schemes including bluesign®, ZDHC, GOTS, and The List by INDITEX. We scored very highly in our most recent bluesign® audit. Our facilities are regularly audited by our partners and we comply with or exceed all of Korea’s world-class environmental, labor, and safety regulations. We have products that comply with CSCL, K-REACH, EU REACH, TSCA, China REACH, KKDK, and other regulatory frameworks. |

|---|

|

| KISCO’s ESG strategy and performance is outlined in our annual report and on our website. We comply with a large number of supplier code of conduct agreements and require similar commitments from our own suppliers. Our policies cover our environmental and safety performance, our social achievements, and our governance compliance measures. Recent initiatives include investing in more efficient waste disposal technologies and the adoption of waste to energy processes. We are constantly improving the sustainability of our products to help our customers to save water, time, and energy. |

|---|

| We have certified a number of our key products under the ECOPASSPORT scheme. However, the vast majority of our products are listed on the ZDHC Gateway and/or in the bluesign® bluefinder. These schemes provide similar certification of products to ECOPASSPORT. One of the key aims of KISCO’s membership of SCTI is to help reduce duplicated certifications across our industry. If you need help understanding how certifications overlap and confirm similar attributes, please contact your distributor. |

|---|

Certification and compliance

| KISCO has over 200 different products registered in the bluesign® bluefinder and a total of over 400 products listed on the ZDHC gateway. In addition, we also have around 150 products registered with GOTS, around 30 registered with ECOPASSPORT and several of our key products certified by GREENGUARD. Finally, KISCO’s data in “The List by INDITEX” covers around 800 different products. Each of these certifications demonstrate the safety of our products against published standards that are designed to eliminate harmful substances. In addition, the bluesign® audit certifies that our facilities and product stewardship processes protect our staff and the environment. KISCO’s commitment to sustainability in our development and supply of fine chemicals for electronics and other application is also strong. We are in the process of aligning our operations with standards set by the Responsible Business Alliance (RBA). Our commitment extends to our food products, which are certified for their purity and compliance with social and religious standards. Lastly, our processes adhere to various International Standards. |

|---|

Warranty

| Product-specific, between 1 to 2 years Storage conditions: UV: Keep below 30ºC and above 0ºC and protect from sunlight and heat. Shake well before use Sublimation: Keep below 30ºC and above 15ºC. Refer to the MSDS for further details Pigment: Keep below 30ºC and above 15ºC. Refer to the MSDS for further details |

|---|

Packaging

| Our standard packaging is a 1L bottle. For custom orders and OEM processing, packaging container size is negotiable. |

|---|

Products

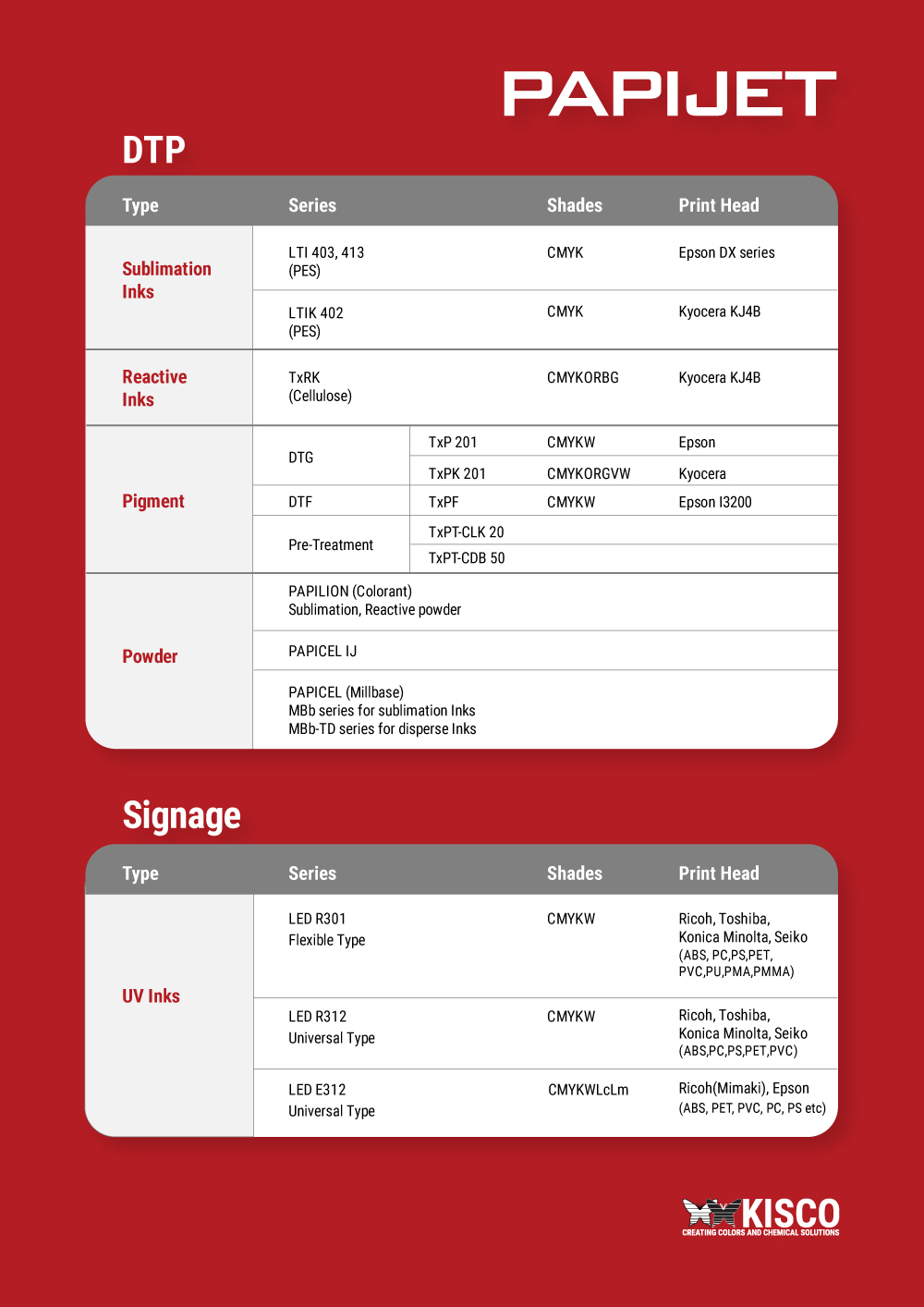

| Please see the attached product list and print head matrix which outlines the range and compatibility of our inks. |

|---|

|

| Our most recently released inks include Pigment Inks: DTP and DTF inks plus pre-preatment solutions UV: UV inks |

|---|