Electronic Materials

KISCO: Leading the development of chemicals for electronics in Korea

KISCO was founded in 1971 and has accumulated world-leading know-how in the synthesis, development and mass production of fine chemicals, dyes and colorants. Over the past decade, KISCO has applied this expertise to also develop materials for use as binders and additives in photosensitisers, photoresists as well as functional coating materials for semiconductors and displays. By expanding beyond its core ink and colorant products, KISCO has established future growth engines and secured its position as a global chemical company.

In order to make the leap into being a high-tech chemicals company, KISCO has focused on research and development on materials for OLEDs, lithography process materials for semiconductors, monomers for Colorless Polyimide (CPI) and graphene-based materials. KISCO has also developed close partnerships to support the development and maintain the localization of these important raw materials.

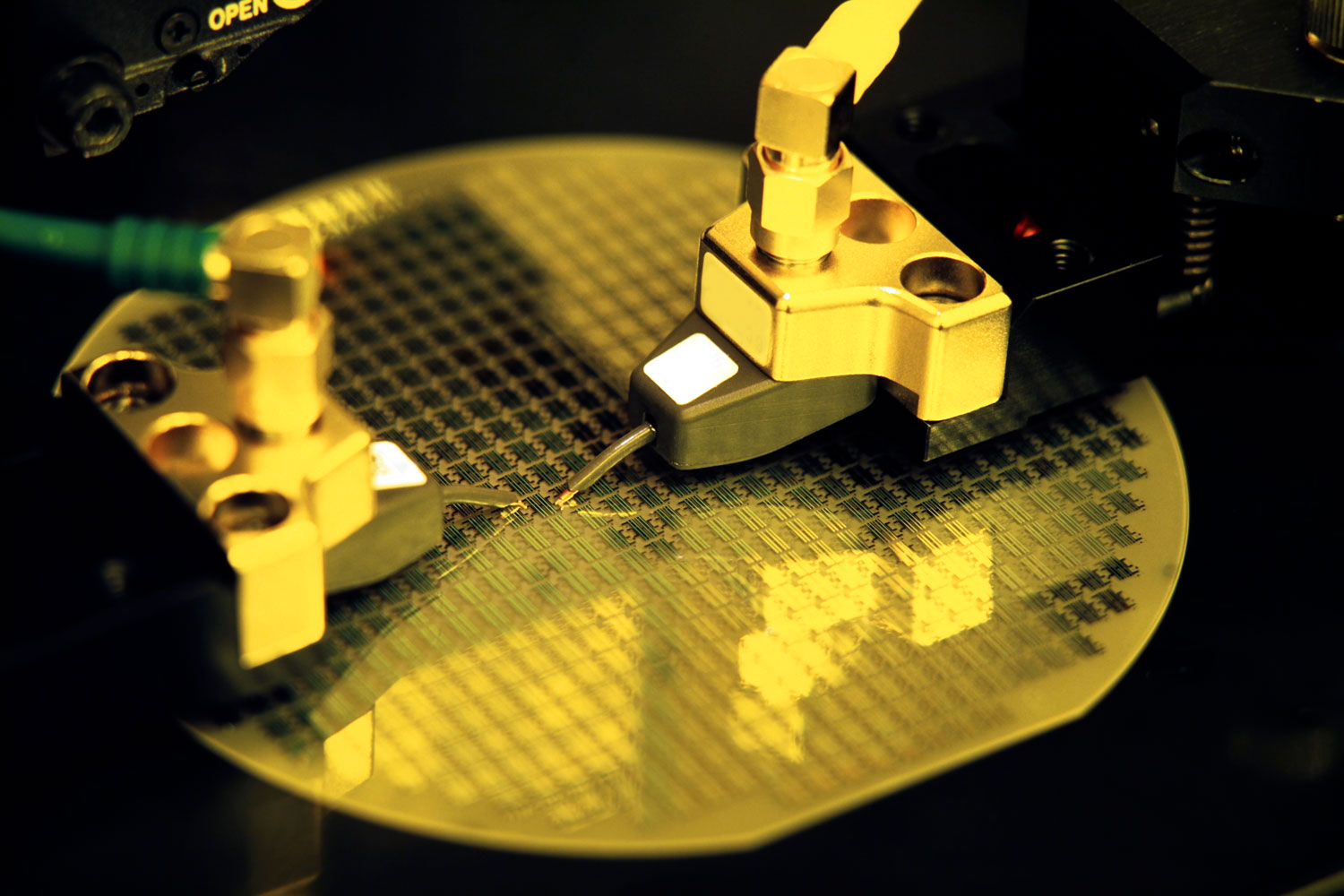

Some of KISCO’s specific research directions include the development of new emissive layer (EML) and common layer (HTL/ETL) material intermediates and process materials for OLEDs. KISCO’s focus is on manufacturing materials with high purity and high reliability, based on its core capability in organic synthesis. KISCO is also developing and producing materials, including small molecules, monomers and polymers, for photo resists, photo initiators, photoactive compounds and photo acid generators for excimer lasers.

With respect to monomers for CPI, through the support of the Korean government’s ‘World Premier Materials (WPM)’ program, KISCO has succeeded in mass-producing the core monomer, which is the most important material for flexible displays, using its own process expertise. This is playing a key role in maintaining the localization of this important technology.

Graphene has been attracting attention for a long time as a dream material with excellent mechanical and electrical characteristics. However, due to difficulties in mass production and high price structures, graphene has not yet been widely commercialized. JMC has recently completed research on the mass production of graphene oxide / graphene and is working on a joint patent application with a Cornell University research team around materials for rechargeable batteries and engineering plastics.

To enable the continued expansion of its research, development and production activities, KISCO is investing in the construction of over 125,000m2 of new facilities in the Iksan 3rd General Industrial Complex, located less than 2 hours from Seoul. This began in 2018 and the first stage opened in Q1 2020.

By investing in its people, its processes, its materials and its facilities, KISCO plans to continue to lead the development and localization of the next generation of materials for electronics.

Inks

DTP

UV

for Dyes